What is the wheel repair machine?

The wheel repair machine is used for repairing scratches on the surface of automobile wheels. Our car will inevitably injure the wheel accidentally in daily driving, causing scratches on the surface of the wheel. A small scratch on the wheel will always affect the wheel and even the overall appearance of the car. If we replace it with a new wheel, the cost will be high, but we can also choose to repair it. There are two ways to repair the surface of the wheel. One is to use a sanding method to smooth the scratches and then paint to repair; the other is to use a wheel repair machine to cut off a very thin layer of material on the wheel surface, usually only need to be cut off less than 1mm, then the entire wheel can be repaired , and you can choose different repair effects, so now wheel repair machines are becoming more and more popular in the auto repair industry.

If you are running a wheel repair shop and want to invest in a wheel repair machine, but you don’t know how to choose it. Based on years of manufacturing experience, we have summarized the 4 reference criteria for you when selecting wheel repair machine

1. Is the overall structure of the wheel repair lathe stable?

Whether the overall structure of the wheel repair lathe is stable depends on the machine bed used by the machine and important accessories. Here I list several important parts, the cast iron bed, the main servo motor, and the linear guide rail.

a. Cast iron bed. The integral cast iron bed has extremely high stability, which can keep the accuracy of the machine tool for a long time. The cast iron bed has good shock absorption performance, which plays a very good role in guaranteeing the repair of the wheels.

b. Servo main motor. It may be unfamiliar to those who don't know much about machinery, but you can understand his advantage by just a little bit. Generally, a relatively low speed is used when the wheel is repaired, and the servo main motor can maintain a good torque at a low speed to ensure the stability of the repair effect of the wheel.

c. 2 axis linear guide rails. The linear rails can make the machine run faster and effectively improve the efficiency of wheel repair. The linear rails has high precision, which ensures the uniformity of the knife pattern and the accuracy of the repair during the wheel repair.

2. Are the components used in wheel repair lathe considered safe? Can it effectively ensure the long-term use of the machine, thereby reducing the failure rate of the machine?

a. The safety of the operator. We have designed a safety protection door, and the operator can’t open the protection door when the machine is operating. The jaws that clamp the wheels are designed with a non-slip groove to prevent the wheel from flying out when it rotates or malfunctions, causing personal injury.

b. The self-protection of the machine. Our wheel repair machine adopts many protective designs to protect the machine itself from failure. I will list a few important points here. The first is the protective cover or protective armor of the guide rails on the two motion axes, which can effectively prevent the aluminum chips entering the guide rails. The aluminum chips are very small, with good viscosity and ductility. If drilling into the guide rail affects the operation of the two shafts, it will have a very large impact on the effect of the wheel repair, and this failure is very difficult to find out. This protective cover may not be installed on the metal processing lathe, but it is very important for the wheel repair machine.

3. Is the overall operation of the wheel repair lathe simple?

Many of the wheel repair machines are technicians in auto repair shops, and they know little about CNC machine tool. Therefore, the operation of wheel repair machines must be simple, convenient and fast. This can improve work efficiency and reduce operating errors. For those who buy wheel repair lathes, it is very important to get the machine to be used quickly.

a. PC control system. The PC control system is a controller independently developed by our company's technical team according to the needs of wheel repair. It effectively gets rid of the responsible operation of the CNC system and solves the difficult problems of user learning and troublesome operation. The software design adopts a more direct and quicker operation method. For example, you only need to move the probe to the starting point and the end point, and then press the button to record the coordinates of the start point and the end point, and then you can detect directly. The whole process is very simple.

b. The vertical structure makes the installation and observation of the wheel very convenient. You only need to place the wheels on the jaws of the chuck and fix it with a chuck wrench. You don't need one hand to hold the hub forcefully and the other to fix it like a horizontal wheel repair lathe. Moreover, the mounting position of the vertical wheel repair lathe is relatively low, and the operator can observe the wheels very conveniently during operation.

c. Automatic tool change device. At present, you can see a lot of wheel repair lathes that use manual tool change. Of course, it is not as convenient as automatic tool change. The most important thing is that you don’t have to worry about whether you operate correctly when you change the tool. The automatic tool changer tool holder ensures the accuracy when changing the tool.

d. Chip removal device. A large amount of aluminum scraps will be generated when the wheel is repaired. The aluminum scraps can be cleaned up in time to keep the machine clean and safe, and make the operator happier to use it.

4. Whether the final wheel repair effect is perfect.

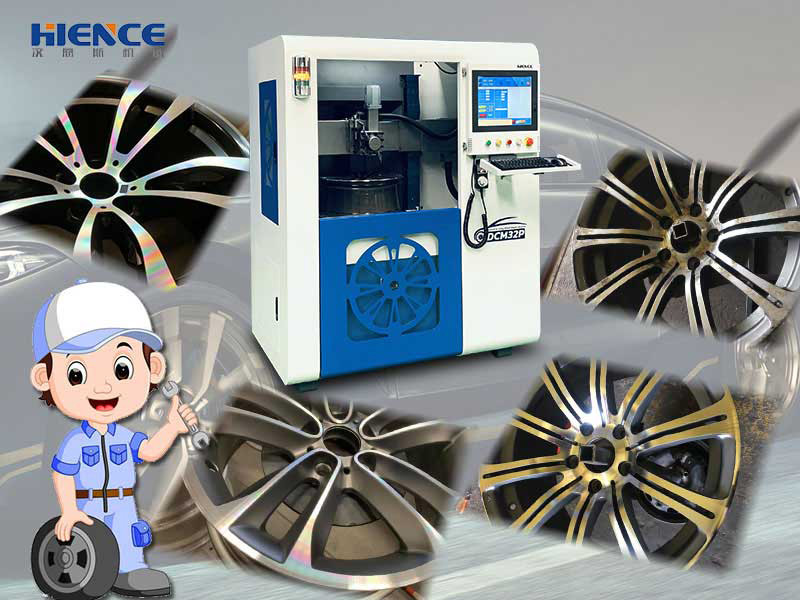

The wheel repair machine is like an artist. The final test of whether the artist is skilled or not depends on the result. The result can also verify the effectiveness of the various designs to ensure the quality of the machine mentioned earlier. The surface of the wheel repaired by a good-quality wheel repair machine is very smooth, the cutting pattern is very uniform, and the effect of the wheel repair can be adjusted. After years of market inspection, our wheel repair machine has been widely recognized by the market. Wheel repair effect can achieve beautiful rainbow line effect, high light mirror effect and big line effect.

These four standards are led by the Marketing Department and discussed by the Technical Department. The conclusions drawn with reference to years of wheel repair lathe production experience and years of market feedback are very valuable for reference. It solves the problem of customers choosing a wheel repair machine before purchase.

Although wheel repair lathe technology and products are very mature, our technical team is still working hard to develop new and better products to meet customer needs according to the needs of the market, hoping to make more contributions for the future automotive repair industry many contributions, and hope to get more customers' recognition of our products, and sincerely look forward to cooperating with you.

Keywords: wheel repair machine

Originally published 01 Dec 2020, updated 01 Dec 2020.