Tom, who runs a professional wheel repair shop in Warsaw, has been a little worried recently. He has more and more customers, especially those who drive good cars, and many of them have scratched wheels. But repairing these mid-to-high-end wheels, especially those with complex shapes, has become increasingly difficult.

Tom said, "Now customers have high requirements. They want to repair them like new, and the lines of the spokes must also be shiny. With old equipment, the repair is either slow or the accuracy is not enough, the rework rate is high, the customer is not satisfied, and I can't make money."

Tom began to look for better equipment in Europe. He learned about one or two European brands, but the prices were high, the wheel repair machine can not good to repair deep dish wheels and the degree of automation was still not ideal. A friend recommended him the HIENCE wheel repair machine from China.

Tom immediately contacted HIENCE company and arranged a video call to demonstrate the machine in action. HIENCE salesman showed how to repair a badly damaged deep-dish wheel.

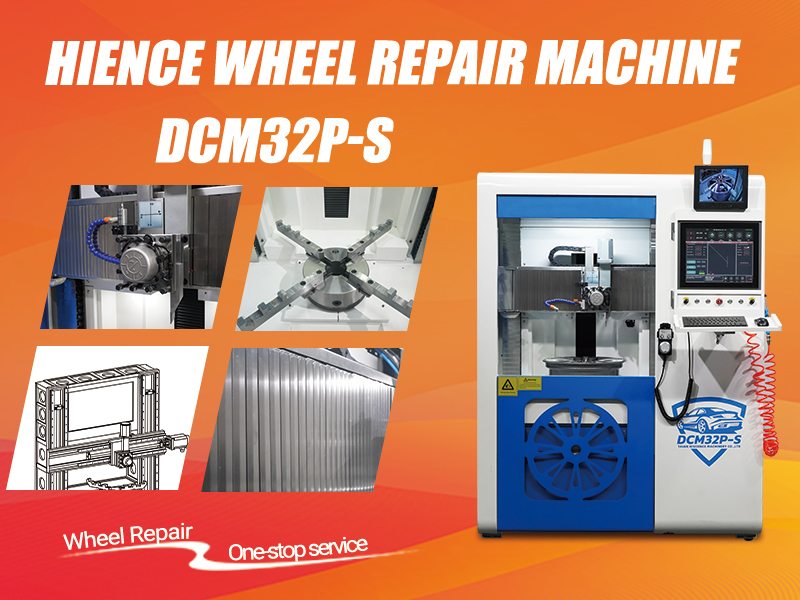

The operation of the wheel repair machine is very fast and accurate. It only takes four steps to complete the wheel repair. First, load the wheel. Second, use the high precision ruby probe to detect the wheel surface. Third, use their special designed optimized software to optimized the detection wheel curve. Finally, diamond cut the wheel surface. Tom noticed that their wheel repair machine used an electric 4 station tool holder not the manual tool holder, and the salesperson told him,"Our automatic 4 station tool post reduces these worries of manual tool post. It has some advantages. First, it can be switched by one key, and the tool change time is fast, which only need 2.6S. Secondly, it is high precision, the repeat positioning accuracy≤(less than or equal to) 0.005mm. Thirdly, it can use long time, the reliability is greater than 100,000 times." That’s unbelievable. Tom says, "it seems the axis move on your wheel repair lathe DCM32P-S is also fast". That's right, because the wheel repair machine's two moving axis are high-speed linear guide rail, which ensures the accuracy and speed of the machine. The linear guide rail is low friction and low noise. Strong interchangeability, convenient maintenance and easy replacement.

Tom said, "I have seen other vertical structure machines in Europe before, but to be honest, I am a little worried about this vertical model, because I have seen vertical machines from other manufacturers shake a little during high-speed operation. Does your wheel repair machine machine DCM32P-S have such a problem?" HIENCE sales staff told Mr. Tom that although they are all vertical models, our structure adopts a gantry frame structure. You may not understand it if I tell you this, but you will understand it if I show you the inside of our machine. 1. The gantry frame structure has extremely high rigidity and stability. The gantry frame structure consists of solid columns on both sides and a top beam (top beam) to form a closed "door"-shaped frame. This structure is naturally excellent in resistance to bending and torsional deformation. 2. Wheel repair is actually the process of turning the wheel surface. Especially when repairing a deformed wheel, a large cutting force will be generated between the tool and the wheel. High rigidity ensures that the machine tool deforms very little when it is subjected to these forces. The extremely high rigidity ensures the stability of the processing process and reduces the vibration caused by vibration, thereby achieving higher processing accuracy and better surface finish. 3. It can also extend the life of the tool: a stable cutting environment reduces abnormal wear of the tool. 4. The wheels you need to repair vary in size (from small cars to large SUVs/trucks), and the wheel surface shapes are different. You need to be able to clamp the wheel, detect the wheel surface and observe the processing process conveniently. At the same time, the portal frame structure can accommodate large-sized wheels: the width design between the two columns can easily accommodate wheels of various diameters, including oversized or wide-rimmed wheels. Although the gantry frame structure may be slightly more expensive and occupy a slightly larger area than the cantilever (C-type) structure, the performance advantages and reliability improvements it brings are crucial for professional, efficient and high-precision wheel repair work. Therefore, high-end wheel repair lathes generally use a gantry frame structure.

For wheel repair experts like Tom who are pragmatic and pursue efficiency and quality, the HIENCE lathe has become a good helper for them to improve their business with its real performance and results.

Keywords: wheel repair machine

Originally published 20 Jun 2025, updated 20 Jun 2025.